Material Selection

1. Linear Polyethylene

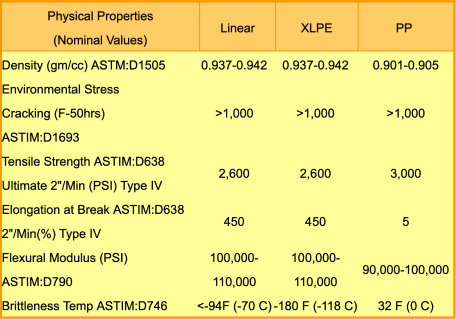

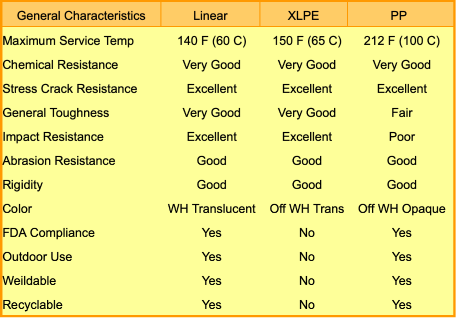

Linear Polyethylene is available as low, medium and high density. Most products offered in this catalog are molded of linear medium density polyethylene (LMDPE) and linear high density polyethylene (LHDPE). They have superior mechanical properties, high stiffness, excellent low temperature impact strength and excellent environmental stress crack resistance. The linear polyethylene used meets specifications contained in FDA regulation 21CFR177.1520 (c) 3.1 and 3.2 and so may be used as an article or a component of articles intended for use in contact with food, subject to any limitations in the regulations. Maximum operating temperature for linear polyethylene is 140° F.

2. Crosslinkable Polyethylene

Crosslinkable polyethylene is a high density polyethylene that contains a crosslinking agent which reacts with the polyethylene during molding, forming a crosslinked molecule similar to a thermoses plastic. This reaction improves toughness and environmental stress crack resistance. Crosslinked Polyethylene (XLPE) is not weldable and does not meet FDA requirement 21CFR177.1520. Maximum operating temperature of crosslinked polyethylene is 1 50° F.