Why Steel Storage Tanks Will Improve Your ROI

In industries requiring the storage of liquids, chemicals, and gases, selecting the optimal storage solution is critical to ensuring operational efficiency, environmental safety, and long-term performance. Steel storage tanks have become a cornerstone in liquid storage due to their unparalleled durability, versatility, and resistance to environmental and chemical elements. That said, we still experience lots of misconceptions surrounding steel storage containers.

At Tank Depot, we provide expert insights into why steel tanks remain a superior choice across various industries compared to other materials such as plastic or fiberglass. Hopefully, by the end of this guide, we will have demystified steel tanks even if a tiny little bit.

Ready? Let’s explore overlooked benefits of steel water tanks.

Importance of Steel Tanks in Water Storage for Fire Protection

Steel storage tanks play a crucial role in fire suppression systems, especially in regions where water availability is limited or where quick access to water is critical. Having reliable and readily available water storage is essential for effectively combatting fires, particularly in emergency situations. Steel tanks are designed to withstand high pressure, ensuring that water can be delivered consistently during fire outbreaks without compromising performance.

- High Capacity and Rapid Deployment

Steel tanks offer large-volume storage, which is critical for fire suppression, ensuring a continuous water supply. - Structural Reliability

These tanks maintain structural integrity even in the most demanding situations, such as extreme heat and pressure surges.

By choosing a steel water storage tank, fire protection systems can rely on dependable water supplies when they are most needed, ensuring both public safety and property protection.

Benefits of Steel Tanks for Fire Suppression Systems

When it comes to fire suppression, durability and reliability are paramount, and steel tanks provide just that. Designed to withstand the intense pressures required for fire suppression, steel tanks ensure that water is delivered without disruption. Furthermore, steel offers excellent fire resistance, which adds another layer of security in situations where external fires might threaten the integrity of storage systems.

- Durability Under High-Pressure Conditions

Steel tanks are engineered to resist the extreme pressures often encountered in fire suppression systems, far outperforming alternatives like plastic and fiberglass tanks. - Fire Resistance

Steel’s inherent fire resistance makes it a superior material for storing water for fire suppression. Even under direct flame exposure, steel tanks maintain their structural integrity, preventing catastrophic failures. - Safety Features

Many steel tanks come equipped with pressure-relief valves and advanced safety features designed specifically to mitigate risks in high-stress environments like fire suppression systems.

This combination of pressure durability and fire resistance makes steel tanks the go-to choice for industrial and residential fire suppression systems.

Compliance with Fire Safety Regulations

In many regions, stringent fire safety regulations dictate the materials and standards for water storage systems in fire suppression. Steel tanks consistently meet or exceed these regulations, thanks to their strength, durability, and the ability to be customized for specific safety features.

- Exceeding Standards

Steel tanks are designed in compliance with industry standards, such as NFPA (National Fire Protection Association) codes, ensuring they can meet the highest levels of fire safety. - Corrosion Resistance for Longevity

By incorporating advanced coatings like galvanization or epoxy linings, steel tanks maintain corrosion resistance, ensuring compliance with long-term fire safety regulations.

Choosing steel ensures not only that your fire suppression system is reliable but also that it adheres to the highest fire safety standards, helping protect property and human lives.

The Strength and Durability of Steel Tanks

Steel has long been recognized for its exceptional strength, making it a preferred material for tanks exposed to harsh conditions. Steel storage tanks offer a level of durability that ensures longevity, especially when managing liquids under fluctuating pressures and temperatures. Unlike plastic or fiberglass, which may warp, crack, or degrade over time, steel tanks remain structurally sound and require fewer repairs, ensuring they serve as a reliable long-term storage solution.

- High Tensile Strength

Steel's mechanical properties, particularly its tensile strength, make it an ideal material for applications where tanks may experience mechanical stress, high internal pressures, or exposure to extreme environmental conditions. - Resistance to Warping

Unlike plastic or fiberglass tanks, steel does not easily deform under heat or pressure, which ensures it remains intact even in extreme temperature fluctuations, making it suitable for a wide range of applications.

Corrosion Resistance and Coatings

A key advantage of steel tanks is their corrosion resistance, which can be significantly enhanced with specialized coatings. Modern steel tanks are typically coated with anti-corrosion agents like epoxy or galvanization, extending their lifespan and minimizing maintenance costs. This makes steel tanks particularly well-suited for outdoor installations or environments where they may come into contact with corrosive substances.

- Galvanized Steel

The zinc coating on galvanized steel tanks provides a robust barrier against rust and corrosion, particularly in environments with high humidity or salt exposure, such as coastal or industrial areas. - Epoxy Coatings

Epoxy-lined steel tanks offer superior chemical resistance, allowing the storage of highly corrosive chemicals, including acids and alkalis, without compromising the tank’s integrity.

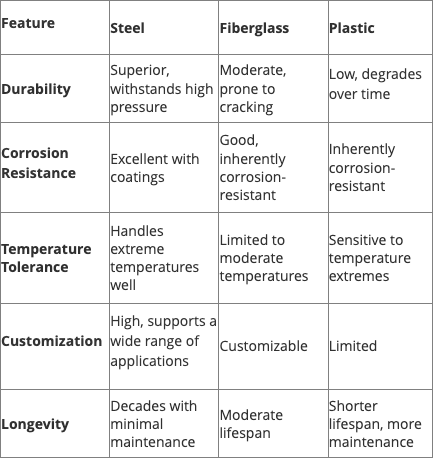

Steel vs. Alternative Materials

When evaluating the choice between steel, fiberglass, and plastic tanks, it is essential to consider the unique advantages steel offers in terms of structural integrity, versatility, and long-term cost-efficiency.

Versatility in Applications

Steel storage tanks are utilized across a broad spectrum of industries due to their adaptability to various storage needs and customizability. Whether storing water, industrial chemicals, or oil, steel tanks offer unmatched versatility. Depending on your unique application, you can choose from a wide range of steel storage units, including corrugated, carbon steel, and galvanized.

- Oil and Gas

Steel tanks are the go-to choice in the oil and gas sector due to their ability to withstand pressurized storage of crude oil, petroleum products, and other hazardous chemicals. - Water Storage

From municipal water treatment facilities to agricultural irrigation systems, steel tanks are valued for their large capacities and durability, providing reliable storage for potable and non-potable water. - Agriculture

In farming, steel tanks efficiently store water, fertilizers, and other chemicals, handling the demanding conditions found in agricultural environments. - Industrial Chemicals

Steel’s resistance to a wide range of chemicals makes it ideal for storing corrosive or hazardous substances necessary for various industrial processes.

Longevity and Cost-Efficiency of Steel Tanks

Although steel storage tanks may have a higher initial cost compared to materials like plastic, their lifespan and reduced maintenance requirements ensure that they provide superior value over time. A well-maintained steel tank can last decades, with minimal operational interruptions due to its robust design.

- Low Maintenance

Regular inspections combined with occasional touch-ups to coatings ensure that steel tanks maintain their integrity for extended periods, unlike plastic or fiberglass alternatives that may require more frequent and costly repairs. - Economical Over Time

The long-term financial benefits of steel tanks, combined with their reliability and durability, make them an economically sound investment for any business requiring large-scale liquid storage.

Customization Options

One of the key benefits of steel tanks is their flexibility in terms of design. Tank Depot works with top manufacturers to offer steel storage tanks that are fully customizable to meet precise requirements.

- Custom Features

Steel tanks can be designed with features such as insulation for temperature-sensitive liquids, corrosion-resistant coatings, or specialized fittings for pumps and valves, ensuring optimal performance tailored to specific industrial applications. - Range of Sizes

From small residential tanks to large industrial tanks, steel storage solutions come in a wide variety of sizes and configurations, making them suitable for different capacities and operational needs.

Safety and Security in Steel Tanks

The safety features of steel tanks further distinguish them from other materials. Built-in mechanisms, such as pressure-relief valves and monitoring systems, enhance operational safety.

- Fire Resistance

Steel's high melting point makes it fire-resistant, a critical advantage for industries handling flammable or combustible substances. - Leak Prevention

Steel’s impermeable structure minimizes the risk of leaks or spills, crucial for protecting the environment from contamination and ensuring the safe storage of hazardous materials. - Structural Integrity

Even under high pressure or mechanical stress, steel tanks retain their shape and strength, making them suitable for storing pressurized gases or volatile chemicals.

Tank Depot Understands All Your Steel Needs

For expert guidance on steel storage solutions, visit one of Tank Depot's locations or contact us to schedule a consultation. Our team is here to help you find the perfect storage tank for your operational needs, ensuring you receive the highest quality and durability tailored to your specifications.